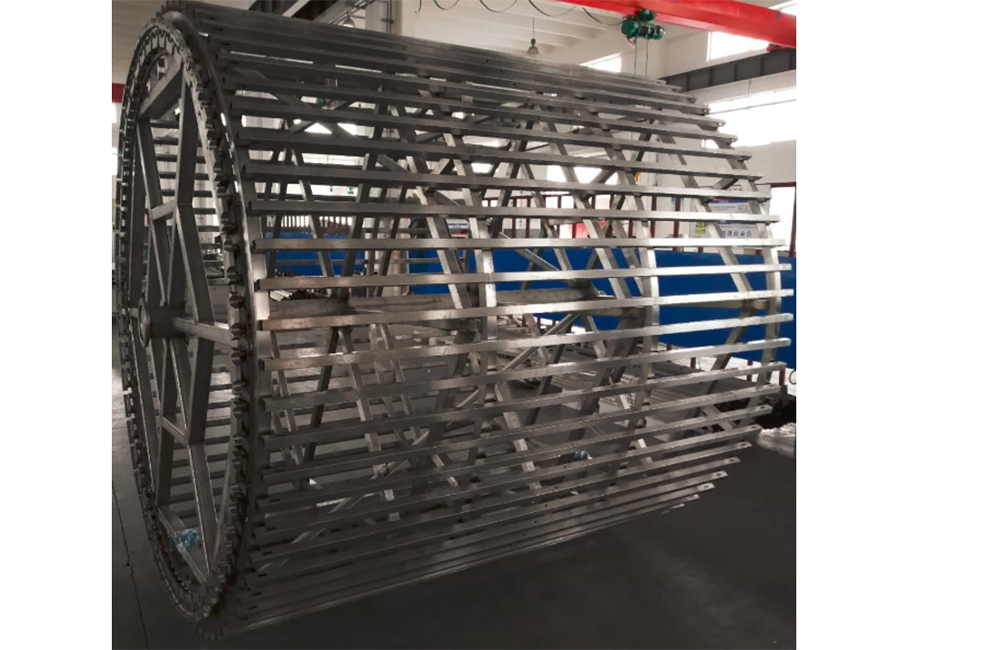

JET New Style Spiral Freezer is based on JET team's over 20 years experience in freezing equipment design and manufacturing, It s originated from Europe design, optimized from conventional spiral freezer and improved accordingly to market demands. JET New spiral freezer is a high efficient freezing system. Product is conveyed on mesh belts doing spiral movement inside freezer to make food fast frozen.

PRODUCT FEATURES:

1.Rational design, safe

and reliable tunning: the design originated from advanced Europe technology.

Double protection, both mechanical and electronic, ensures reliable running.

2.Simple operation and easy cleaning and maintenance: freezer can be operated

only after simple training, no special requirement. Sloped and fully welded

base structure is easier for cleaning and faster drainage. Inside space is

larger for easier maintenance.

3.Convenient and flexible production operation: more flexible in input and output

direction options and also easier to match with other equipment, realizing

streamline production.

4.Double sided stainless steel insulation enclosure: enclosure plate is made by

high-quality double sized stainless steel with polyurethane inside. The

enclosure door is made with double-layer sealing strip, and equipped with a

heater to prevent freezing.

5.Stainless steel structure: the structural components is made of stainless steel

material, including main driving chain wheel, chain, bearings and bearing seats

in the belt driving parts.

6.Conveying belts are made of high strength SUS304 spiral mesh. High frequency

induction heater is used for rod header forming that lead to more stable

running and longer life.

7.Evaporator: made by industrial level Aluminum alloy, like tubes, fins. Dense

tube configuration to optimally transfer heat.

8.Reliable driving control and stainless PLC: spiral movement is from Europe

technology, belts operation is under variable frequency control, belt moving

speed is stepless adjustable.

JET New spiral freezer is widely applicable for aquatic product and seafood, hot pot product, meat products, pastry, poultry, ice cream, bread dough fermentation, etc

|

Model |

Dimension (mm) |

Base Load |

Dia of Drum |

Freezing Capacity (Kg/h) |

Belt Width (mm) |

Product Height Limit |

Spiral Tiers |

| JNS1*6112 | 6300*4790*3300 | 15KW | 2000mm | 500 | 610 | 55-175mm | 12 |

| JNS1*6512 | 6900*5350*3300 | 20KW | 2500mm | 750 | 650 | 12 | |

| JNS1*7118 | 7200*5410*4300 | 30KW | 2500mm | 1000 | 710 | 18 | |

| JNS1*8118 | 8500*6250*4300 | 40KW | 3000mm | 1500 | 810 | 18 | |

| JNS1*9124 | 9500*6350*5300 | 50KW | 3000mm | 2000 | 910 | 24 | |

| JNS2*6112 | 11600*4790*3300 | 33KW | 2000mm | 1000 | 610 | 12 | |

| JNS2*6512 | 12800*5350*3300 | 39KW | 2500mm | 1500 | 650 | 12 | |

| JNS2*7118 | 13600*5410*4300 | 45KW | 2500mm | 2000 | 710 | 18 | |

| JNS2*8118 | 15800*6250*4300 | 62KW | 3000mm | 3000 | 810 | 18 | |

| JNS2*9124 | 16500*6350*5300 | 82KW | 3000mm | 4000 | 910 | 24 | |

|

Referenced product |

Dumplings |

Infeed temperature: 15℃, Outfeed temperature: -18℃ |

|||||

|

Optional |

Infeed & Outfeed direction, Tier spacing, Fan quantity, Total tiers, Rotation direction, Belt width (520mm---1060mm) |

||||||

| Tailored design as per customer requirement | |||||||